|

|

|

Supply technique |

| |

|

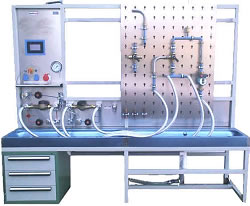

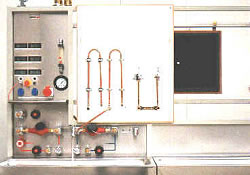

| This universal work and test bench is

designed for use in nearly all themes of supply techniques. The basis stand

is equipped with high quality measuring systems. It is combined with pre-installed

experimenting boards. The result is a multimedia training center for theoretical

and practical education. , the and the modular system for self-assembled

build-up. |

| |

Available experimenting boards:

- Static & dynamic pressure

- Flow resistance of armatures

- Waterhammer of fast closing armatures

- Pressure loss in pipelines

- Pressure loss by sharp angled bows

- Characteristics of the centrifugal circulating pump

- Series connection of pumps

- Performance of a mixing valve (cold run)

- Performance of an electric boiler

- Performance of a gas boiler

- Boiler and monolever mixing valve

|

- Performance of a thermostate controlled mixing valve

- Current & water consumption of household units

(washer etc.)

- Dilation of pipework with temperature

- Noise reasons and -sources

- Air- and solid conducted noise

- Installation rules for drinking water protection

- Security installations for waterheaters

- Touchfree armature

- Performance of the combi therme

- 3- & 4-way mixing valves and their hydraulics

- Drain water piping

|

| |

Modular system:

The modular system provides individual build-ups with

usual elements. Fixing is performed by socket joints, inserted in an array

of key-hole like receptibles. Connection is done by threaded joints and

flexible wave-pipes made by Meibes. |

| |

Technical details:

| Dimensions: |

2.4m x 0.6m x 1.95m |

| Weight: |

180 kg |

Services:

|

400V AC 3ph. 25kW |

| Water supply: |

Cold and hot water 3m³/h |

| Gas supply: |

Gas (bottled gas) |

|

|

| |

| Experimentor guidance |

| |

| U2000 provides a PC-based experimentor

guidance, supporting the user in getting quick and correct test results.

During test performance the PC displays messages and instructions dependent

on the current situation. Operation mistakes will be detected early and

can be avoided. |

| |

| Example: Determination

of 3 way mixing valve characteristics. |

| |

|

| Universal view: This is the standard screen display.

All measured quantities are displayed. |

|

|

| Request to depress the unit. RW and RK must be

turned to "open". It will be continued if U2000 is depressed. |

|

| |

|

|

| The unit is depressed, the test build-up can be

assembled according to the scheme. |

|

|

| The build-up is ready and can be filled up with

water. It will be continued automatically when the build-up is pressurized. |

|

| |

|

|

| Message for the adjusting of the test parameters. |

|

|

| Input of the pump power. The input is instantly

controlled for plausibility. |

|

| |

|

|

| The varied parameter position of the mixing valve

is adjusted. A data-set will be applied with button "Acquire". |

|

|

| Evaluation of the test result. |

|

| |

| Example test evaluation created with the

included software package for Windows 95/98/NT/XP/2000 |

| |

|

| |

|

| Available experimenting

boards |

| |

|

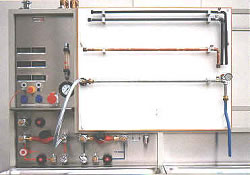

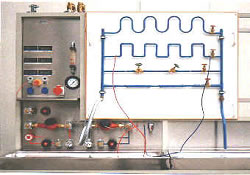

| Armature test with auxiliary panel |

|

|

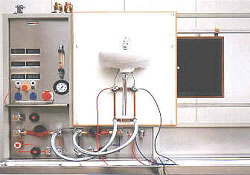

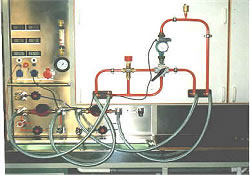

| Armatures test directly |

|

| |

|

|

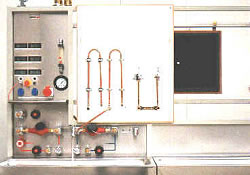

| Armatures test directly |

|

|

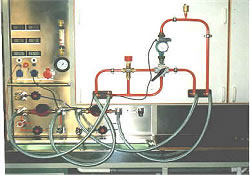

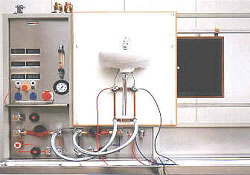

| Security armatures |

|

| |

|

|

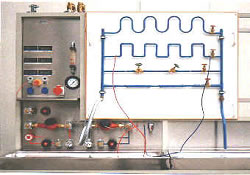

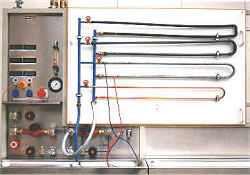

| Friction pressure loss in pipes |

|

|

| Impulse pressure loss |

|

| |

|

|

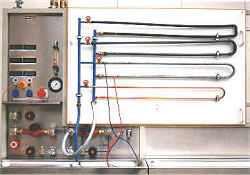

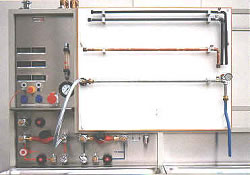

| Dilation by temperature |

|

|

| Noise reasons |

|

| |

|

|

| Noise absorption |

|

|

| Rack for boilers with exchanger |

|

| |

|

|

| Protection of drinking water |

|

|

| Touch-free armatures |

|

| |

|

|

| Drained water technique |

|

|

| 3- and 4- way mixing valve |

|

| |

|

Stichworte: Prüftisch, Montagewand,

Prüfwand, Heizungstechnik, Sanitärtechnik, Rohrleitungsbau, Installationstechnik,

Versorgungstechnik, Wassertechnik, Lüftungstechnik, Versuchsanlage, Versuchswand,

Modularbeitsplatz, Heizung, Klima, Sanitär, Versorgungstechnik |

| |

|

| ©TeLC Unna 2004 |

1976

1976