1976

1976Dipl. Ing. A. Kutschelis & Sohn

Technische Lehrmittel Construktion

D- 59425 Unna

Germany

web: http://www.telc.de

mail: mail@telc.de

phone.: +49 (0) 2303 239999

facs: +49 (0) 2303 239990

| printable version | Aircooler and dehumidifier | |

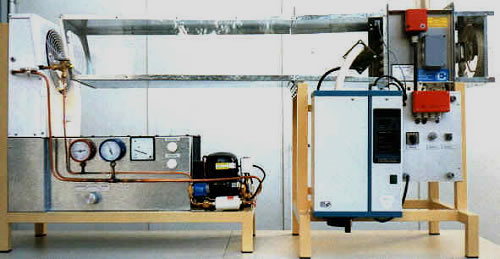

| For profund training in air-conditioning it is necessary to understand the processes aircooling and airheating. Aircooling is a precondition for dehumidifying and airheating a precondition for humidifying. These physical facts base on the effect that air absorbs the more water the higher is its temperature . Exceeding the limits effects condensate or rain. TeLC has designed two units to do training in these subjects. Both devices can be used combined or isolated. The above photo shows the aircooler. | |

Systems:

|

||

Measuring systems: The unit can be equipped with electronic sensors digitally connected to the internal controller, sending serial data to an external PC. Stand control and data acquisition is performed by Windows-software. Measured quantities are:

|

||

Details:

|

||

Keywords: Aircondition, Aircooler ,Air heater,

humidifier, Climate, Air-conditioning, Climatic Chamber, Air-conditioned,

Air-moist, Relative Humidity,Wet Bulb Temperature, Humidity Ratio, Humidifier,

Humidification of air, Ait Pressure, Atmospheric Pressure, Cooling Water,

Cooling System, Cooling Liquid, Cooling Media |

||

| ©TeLC Unna 2004 | ||

| printable version | Airheating and humidifier | |

| ||

For profund training in air-conditioning it is necessary to understand the processes aircooling and airheating. Aircooling is a precondition for dehumidifying and airheating a precondition for humidifying. These physical facts base on the effect that air absorbs the more water the higher its temperature is. Exceeding the limits effects condensate or rain. TeLC has designed two units to do training in these subjects. Both devices can be used combined or isolated. The above photo shows the combined build-up. The airheater unit on the right is blowing into the aircooler unit on the left. |

||

Systems:

|

||

Measuring systems: The unit can be equipped with electronic sensors digitally connected to the internal controller, sending serial data to an external PC. Stand control and data acquisition is performed by Windows-software. Measured quantities are:

|

||

Details:

|

||

Keywords: Aircondition, Aircooler ,Air heater,

humidifier, Climate, Air-conditioning, Climatic Chamber, Air-conditioned,

Air-moist, Relative Humidity,Wet Bulb Temperature, Humidity Ratio, Humidifier,

Humidification of air, Ait Pressure, Atmospheric Pressure, Cooling Water,

Cooling System, Cooling Liquid, Cooling Media |

||

| ©TeLC Unna 2004 | ||

| printable version | Aircondition test stand | ||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||

Aircondition unit in industrial segmented design with modern steam humidifying, cold water coolers / dehumidifiers and detailed measuring devices. Wide range of airtreatment through combination of 2 treating units: One for the production of the environmental condition, the second for the conditioning of the entry situation. The entry situation is independant from the room or the outside climate. The two conditioners contain the same treating equipment. The cold water generator for the cooling exists only once for the sharing or concentrated cooling only in the one or the other part. The cold water unit is very practical for the reversing and the measuring. Additional equipment like air mixing section or cooling tower are possible, also reduction of equipment. |

|||||||||||||||||||||||||||||||||||

Measuring and control systems: All equipment is of industrial standard and grant for

high efficiency, long life and little maintenance. Heaters, fan, humidifiers

and valves are controlled by PC and touch-screen.

|

|||||||||||||||||||||||||||||||||||

Technical details:

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

Keywords: Aircondition, Aircooler ,Air heater,

humidifier, Climate, Air-conditioning, Climatic Chamber, Air-conditioned,

Air-moist, Relative Humidity,Wet Bulb Temperature, Humidity Ratio, Humidifier,

Humidification of air, Ait Pressure, Atmospheric Pressure, Cooling Water,

Cooling System, Cooling Liquid, Cooling Media |

|||||||||||||||||||||||||||||||||||

| ©TeLC Unna 2004 | |||||||||||||||||||||||||||||||||||